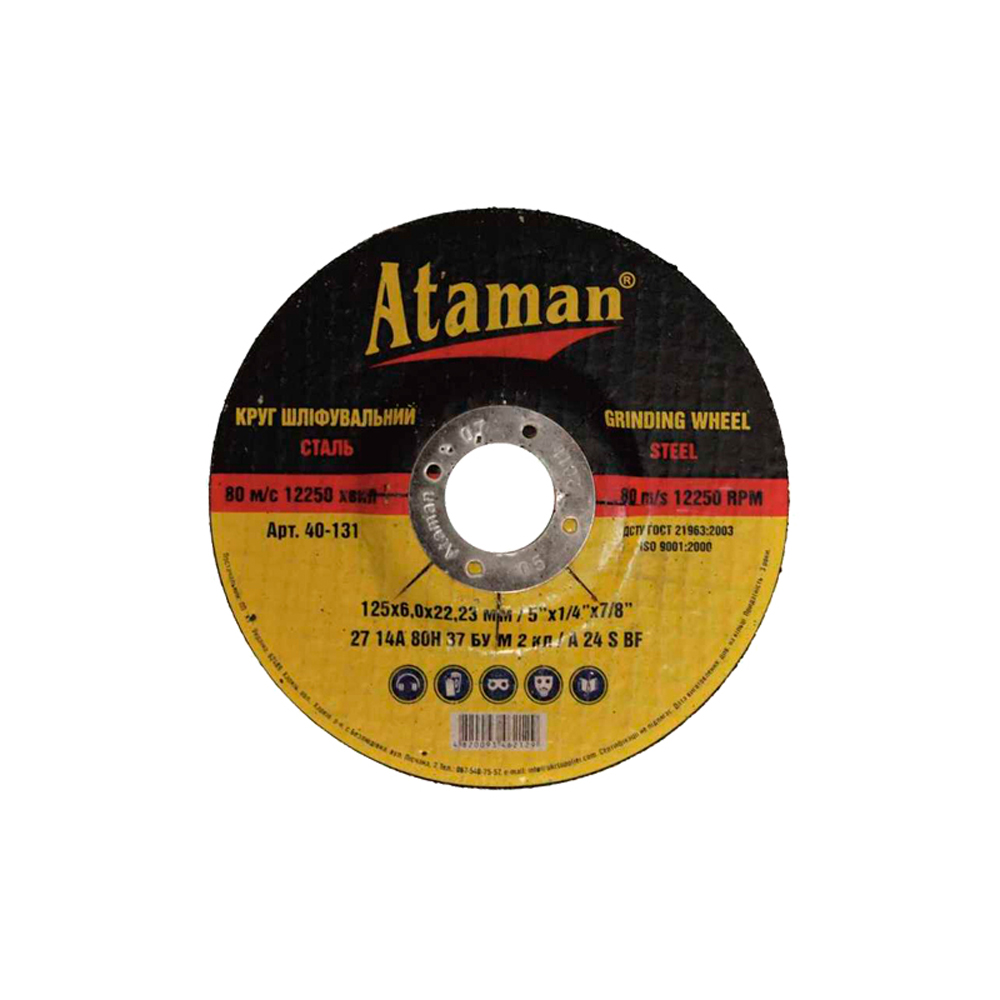

A versatile

tool for operations requiring significant metal removal: cleaning welds,

preparing surfaces for welding, chamfering, descaling, deburring, welding

spatter - grinding wheels. The disc can machine a plane, an edge, an internal

fillet and parts of complex geometric shapes.

Butt wheels

for metal appeared on the market relatively recently. The grinding wheel opens

up new possibilities for machining surfaces, removing spatter and burrs from

weld seams. The main condition for the end wheel cleaning operation for angle

grinders is low speed. Profile and end discs are especially suitable for

removing tarnish from welded lines on stainless steel products and for

roughening the surface for successful bonding (bonding). In some cases, the

product is especially suitable for highlighting the structure of wood.

But

whatever they are called, their main feature in comparison with other abrasive

elements is the aggressive cleaning of materials from rust, scale, paint,

varnish and much more.

Does not

damage the part itself. How could this happen? First of all, the element is

very elastic, which makes it possible to clean it without damaging the surface

of the product.

The grinding

wheel is also effective due to its open abrasive grain structure, which

prevents abrasion and overheating, extends tool life and ensures consistent

machining quality.

This

combination of properties makes these scrapers an excellent replacement for

wire brushes and various chemical compositions for cleaning metal surfaces.

At the same

time, the product has a number of outstanding advantages:

The element

is used in specific works on metal:

With the

help of a universal grinding wheel, you can quickly and efficiently perform

grinding work on surfaces of any complexity: edge, corners, plane.

All disks

have significant differences in terms of such indicators as:

When

choosing a grinding wheel for a metal grinder, it is important to remember that

the dimensional volumes of the disc must exactly match the parameters of your

power tool, it is important and correct to take into account the rotation

speed.