Forged products

and their application in design and style play an important role today, and in

many cases it is absolutely impossible to do without forged rivets as a

camouflage element. And one thing to consider from the start is that design is

a major part of the process when creating these products. All for the reason

that when a customer presents a finished sketch of a future product, he will be

able to calculate the number and cost of forged elements, as well as what

percentage of manual work will be used in this case and what is the total cost

of work with the product.

the total cost

of work with the product.

Elements of

decorative art forging are not just a direction associated with metal

processing, it is a continuous creative flight towards metal processing. These

are unique design ideas, not non-standard solutions to complex problems posed

by the customer. In other words, all this can be called the "flight of

fantasy" of the master, who embodies the most sophisticated ideas into

reality.

At some point in

the twentieth century, elements of artistic forging were temporarily forgotten

and abandoned. All this is due to the fact that conveyor production was

developing against the background of forged products, so forging and exclusive

metal objects were out of the question. Time passed, and the craftsmen and

blacksmiths did not stand still. They found time for their favorite work and

discovered the unique beauty and sophistication of this type of product. And

there is no doubt that forged exclusive items have received a good boost today

and are in demand by everyone, regardless of their financial situation. And

this fact is absolutely easy to explain, because the products are made directly

by cold forging and are multifunctional.

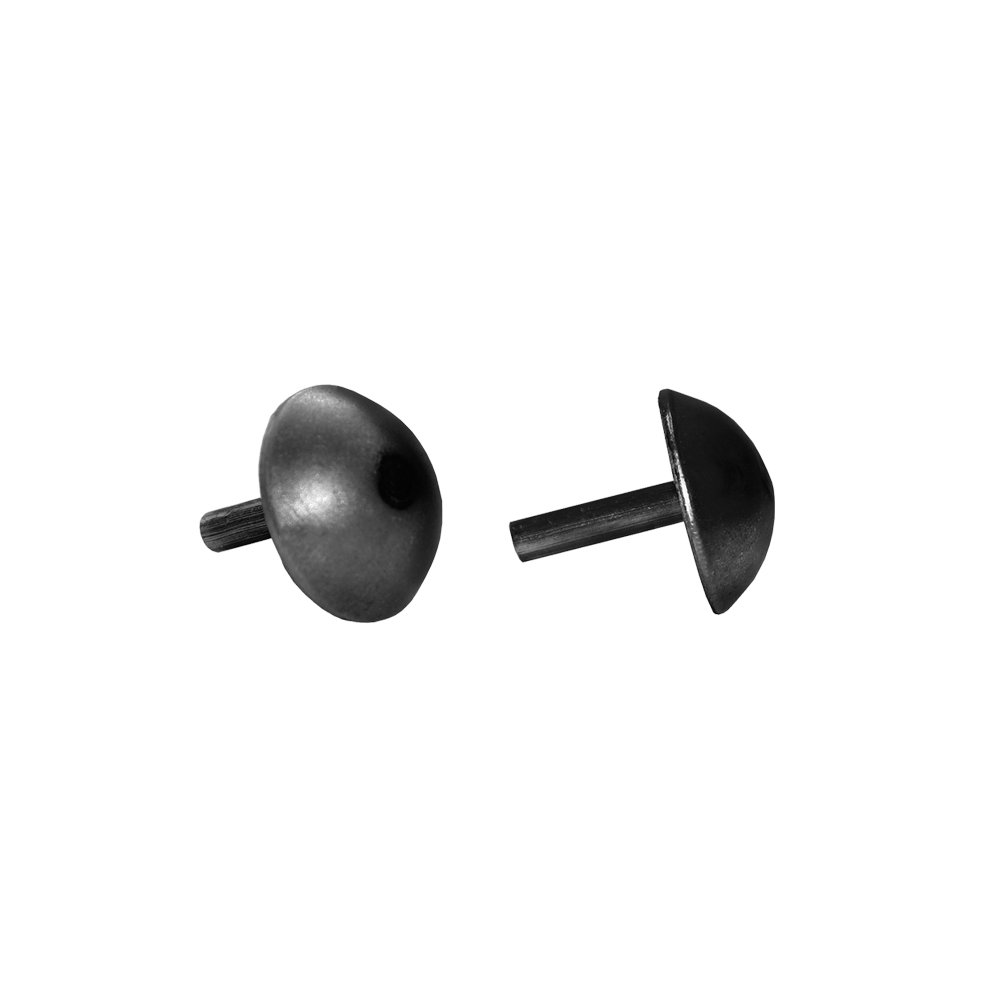

Forged rivets are

actively used in the manufacture of metal products. Thanks to the wide variety

of heads, they are perfect for decorative purposes Traditionally, the main

purpose of their use is to connect the details of the structure of products to

each other.

The advantage of rivets

The advantage of rivetsThe use of this

type of fittings in the manufacture of products plays a huge role, therefore

there are many advantages that can be distinguished for this type of component.

The main

advantages of rivets include:

The area of

application is quite extensive – they are used to connect forged parts and

their design. Where the rivets are used depends on their size.

their size.

Buying or

ordering forged rivets has never been easier. You can view the assortment on

the website in the appropriate size.

The abundance of

shapes and sizes of art forging parts makes them ideal for decorating metal

products. Also, they do an excellent job with their main function – fixing the

constituent structure of the structure.