Accessories for

power tools that are designed for fast and accurate cutting of various parts

and structures from different materials - cut-off wheels. They differ in outer

diameter, hole size, thickness, grain volume and abrasive composition.

size, thickness, grain volume and abrasive composition.

As a rule, all

elements are reinforced with a special mesh, which gives them additional

strength. It is not recommended to use instances without it.

Cut-off wheels

are indispensable for various assembly and finishing works in turning and

locksmith shops. You can buy for cutting some abrasive materials and metal:

corners and channels, pipes and rods, cast iron blanks and stainless steel

sheets, stone slabs and bricks, tiles, granite and limestone, various elements

of wood.

The raw materials

used for the manufacture are silicon carbide or electrocorundum (including

zirconium). A bunch of bakelite or vulcanite with or without reinforcing

components.

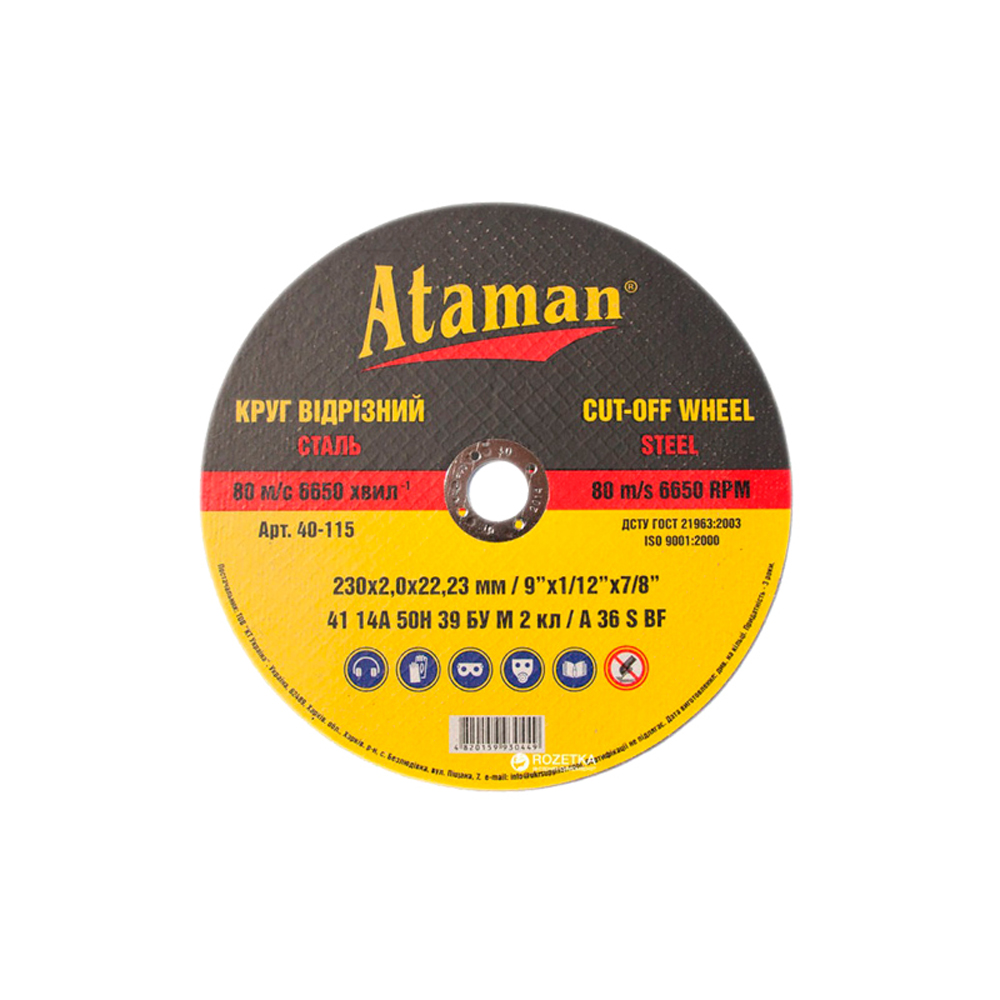

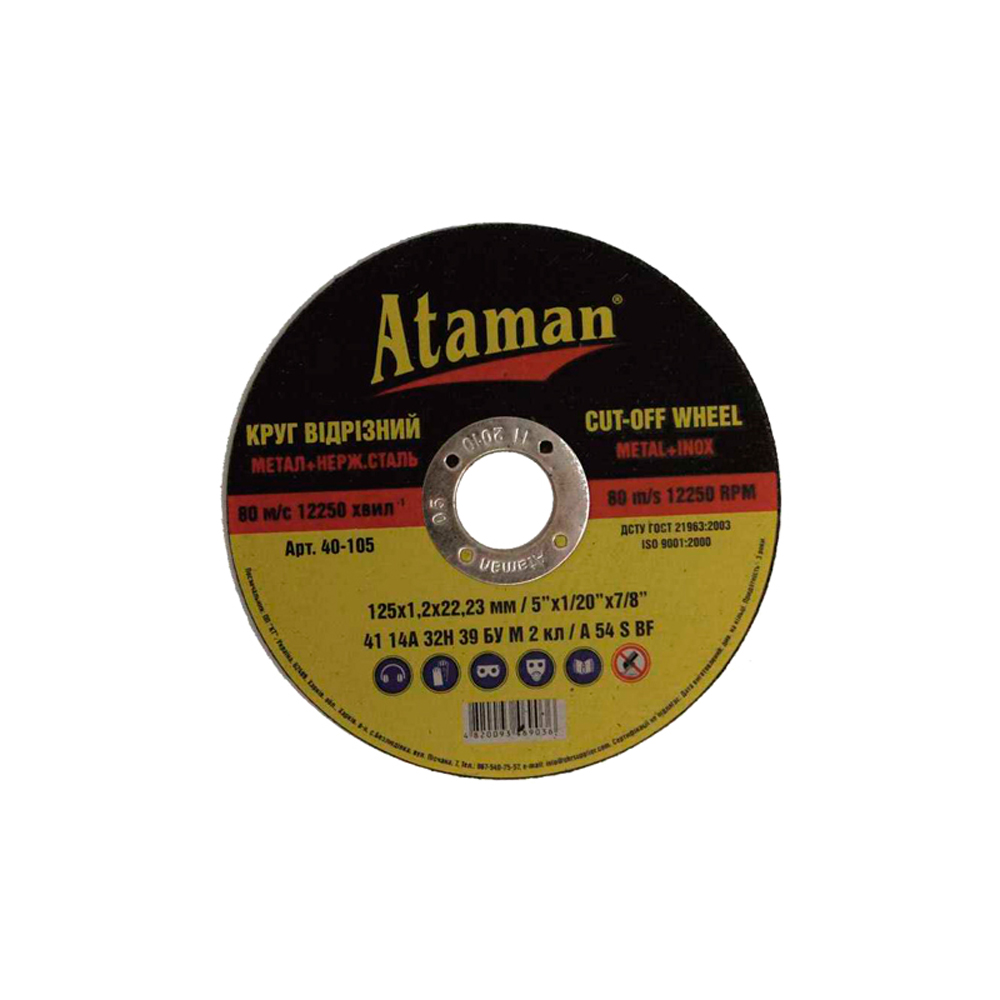

Many years ago,

wheel markings and specifications left a lot to be desired. It was difficult to

read, only an experienced specialist could figure it out. For our days, this

data has been simplified. If an element bears the inscription “A 30 SBF”, it means

that the cutting discs are made of abrasive grains of iron, sulfur and

chlorine. S is a measure of hardness. The higher the ordinal number of the

symbol, the higher this indicator. You should not buy products with the maximum

level of hardness, because the head can be overheated, and the cutting

particles of the abrasive are poorly cut. As a result, it is not possible to

get a neat seam.

Terms of use of circles

Terms of use of circlesEach disk has its

own lifespan. This must be taken into account. If it is over, the cutting discs

cannot be used. Even if the product looks like new, and there is no suspicion

of destruction and damage to the structure of the material. When working with

stone or metal, it is recommended to purchase cutting discs immediately before

starting work. Better not to buy them in reserve.

Wear during

operation directly depends on the properties of the discs themselves and the

material being processed.

More than 80% of

all operations performed with a grinder relate to cutting. When choosing

cut-off wheels, pay attention to the features and functionality associated with

the element. For example, some blades are designed for cutting metal, while

others are only for cutting stone. Cut-off products are divided into diamond

and abrasive. All main characteristics are indicated on the front of the

circle:

There are also

universal cutting wheels on sale, but they are mainly intended for home and

domestic use.

The main power

tools available on the market are multifunctional products. They owe this,

first of all, to special devices and attachments. Each of them has its own

specific characteristics, goals and properties. A striking example of a multifunctional

tool is an angle grinder (in common people - a Bulgarian).

characteristics, goals and properties. A striking example of a multifunctional

tool is an angle grinder (in common people - a Bulgarian).

Consists of a

body, motor, motor, attachment and power button. Depending on the disc

installed, the sander can be used for both cutting and processing materials

such as stone and metal.

Regardless of the

material to be processed, the following points must be considered when using

the power tool:

In order to

select the necessary components for metal processing, you can contact the

manager and get the necessary advice, or leave a request for a call from the

product page.