Forged

elements and structures made by the Artdeco® manufacturing company are sold

without processing and painting. Therefore, when buying products, you will need

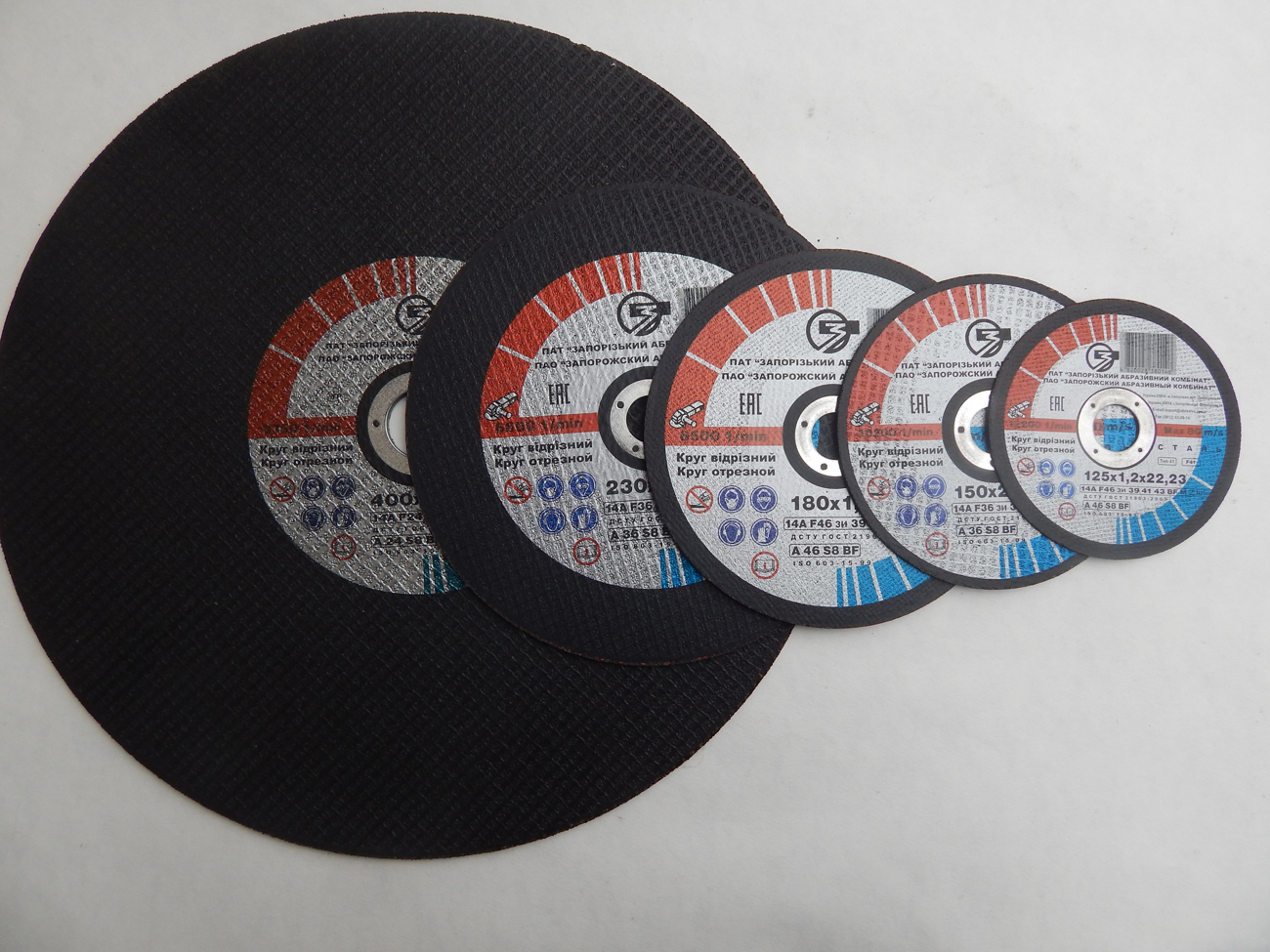

consumables for processing a metal surface, such as discs - grinding, cutting,

trimming, stripping, welding wire, metal combs, brushes, gloves, welding

electrodes and other consumables.

Forged

elements and structures made by the Artdeco® manufacturing company are sold

without processing and painting. Therefore, when buying products, you will need

consumables for processing a metal surface, such as discs - grinding, cutting,

trimming, stripping, welding wire, metal combs, brushes, gloves, welding

electrodes and other consumables.

The items

for surface treatment include wire for a semi-automatic machine, the quality of

which affects the ability to weld various metals, the quality and durability of

the seam and its strength.

The price

for consumable wire depends on the type, diameter and weight of the coil. The

diameter is selected according to the metal thickness: the thicker the metal

being welded, the larger the wire diameter. You can calculate the amount of

wire using the conventional formula: multiply the total mass of the structure

by 1.5 and divide by 100, which is approximately 1.5% of the weight.

Copper-plated

welding wire has a thin copper coating that protects steel from moisture and

prevents rust. Guaranteed quality and reliability of the firmware, resistance

to mechanical damage to the connection.

Choosing consumables

for a novice welder can be a challenge. For example, what electrode diameter is

needed for a specific consumable thickness, or what welding current must be

adjusted to get a strong weld?

The

electrode is a consumable metal core with a special coating called a coating.

During welding, the core melts, and during combustion, the coating creates gas

protection of the seam from the harmful effects of oxygen. In addition, during

the welding process, a protective slag layer is formed from the molten pool.

When

choosing an electrode, it is necessary to pay attention to the composition of

the core, which should be similar to the metal being welded. Therefore, there

are special electrodes for carbon, alloy, high alloy alloy, for work with

stainless steel, heat-resistant, for performance with aluminum or cast iron.

There are a

huge variety of metal alloys, we will not talk about them, but focus on those

electrodes that may be needed in everyday life. Lightweight structural steel is

mainly used for domestic needs. There are 4 types of coatings: basic, rutile,

acidic and cellulosic. Each of them is used to solve their own problems.

A roughing

wiper blade must have a fixed thickness of at least 6 mm, which is different

from the cutting wheel, and also have a corrugated or rough surface, which is

necessary, in particular, to reduce the temperature of the crushed (cleaned)

material. Usually such a circle is also equipped with a metal sleeve to

strengthen its structure.

Consumables

for the production and work with metal substrates are constantly needed,

because the surface must be treated with high quality and at the lowest cost.

The

grinding wheel can be installed on a drill, grinder or any other grinding

mechanism that requires work that requires increased safety requirements,

especially for those who perform such actions for the first time:

Cut-off wheels for metal are designed for cutting materials from various steels and alloys with a hand-held power tool (landing diameter 22 mm.) Or on machine tools (diameter when landing 32 mm.)

A grinding wheel is an abrasive cutting tool consisting of a colossal amount of hard and solid particles; they are located around the entire perimeter of the product. Processing occurs by removing excess layers, which come off in the form of small chips.

A variety

of work gloves or mittens with wide elongated cuffs are often used as a

reliable consumable material during work. As a professional protection, gaiters

are usually designed for high temperatures. This consumable protective material

is mandatory for:

Leggings

can be made of synthetic materials or split leather - natural leather of cows,

bulls and buffaloes. To fully answer the question of what split leggings are,

you need to delve into the process of making this material.

When

choosing consumable work gloves, pay attention to the seams, as these are the

most vulnerable places. Quality models are always sewn with Kevlar thread,

which makes them more reliable and resistant to damage. Sutures are often

covered with pieces of leather for added security.

For the

processing of forged elements, you need consumables that you can purchase on

our website.