The main

consumable for welding in the manufacture of metal structures and the repair of

all types of metal products, wire for welding. None of the industries can do

without the use of welding wire, such as shipbuilding, mechanical engineering,

metal structures, bridge construction.

What is it

used for? Small diameter welding wire is used for car repair and door making.

Large diameter is used in the manufacture of metal structures and pipe welding.

In the

process, the rod melts and fills the weld zone, being the filler base. For a

good connection, the structure of the welding wire must match the composition of

the parts to be welded in terms of its chemical and physical properties.

Accordingly, the solid wire rod is divided into bronze, aluminum, stainless

brass, steel and others.

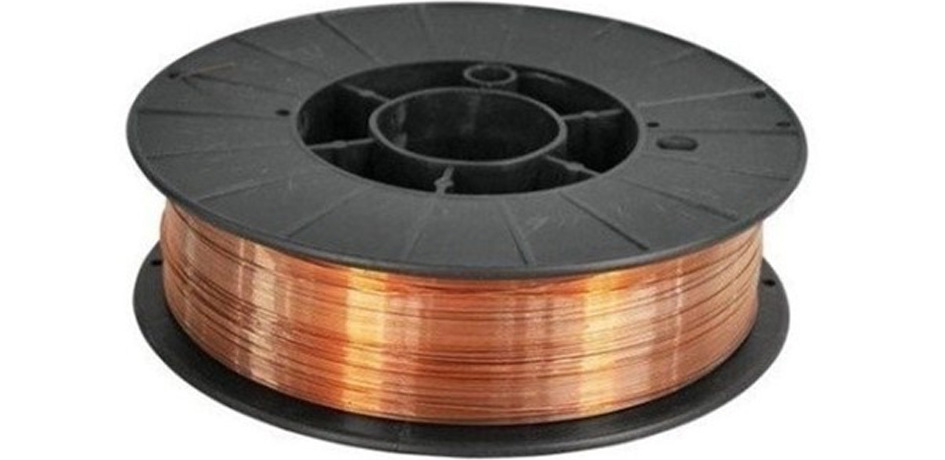

Semi-automatic wire

Answering

the question of how to choose consumables for a semiautomatic welding machine,

first of all, it is  necessary to determine the type and thickness of the metal

for welding. Remember the main thing, the closer the product composition is to

the base metal, the better the welded joint will be.

necessary to determine the type and thickness of the metal

for welding. Remember the main thing, the closer the product composition is to

the base metal, the better the welded joint will be.

Process

space is equally important. For example, if work is done in a garage or a large

production hall.

The diameter ranges from 0.6 mm to 2 mm.

- 0.6;

- 0.8;

- 1;

- 1.6;

- 2.

But the 2mm

is usually used in serious industries. For each diameter, you need to choose a

suitable nozzle. This means that the hole must match the wire used.

As for the

weight of the coils themselves, they range from one to fifteen kilograms.

Calculation and correct

choice of material

- How to calculate the amount of welding wire?

For example, if the process is carried out in a small production facility, it

is economical to use five kilogram coils.

- How is the diameter of the welding wire

selected? Must match the thickness of the metal you will be welding.

If you

choose aluminum, then it must be welded in a protective gas environment - argon

or helium.

There are a lot of types of welding wire:

- Steel with copper-plated coating;

- Stainless;

- Powder;

- Aluminum;

- Copper;

- Steel.

Wire types

- Solid section - can be made of steel, copper,

aluminum and alloys of these metals. Copper-plated is used to work with

unalloyed and low-alloyed steels, with

metals containing aluminum, magnesium,

manganese and silicon.

metals containing aluminum, magnesium,

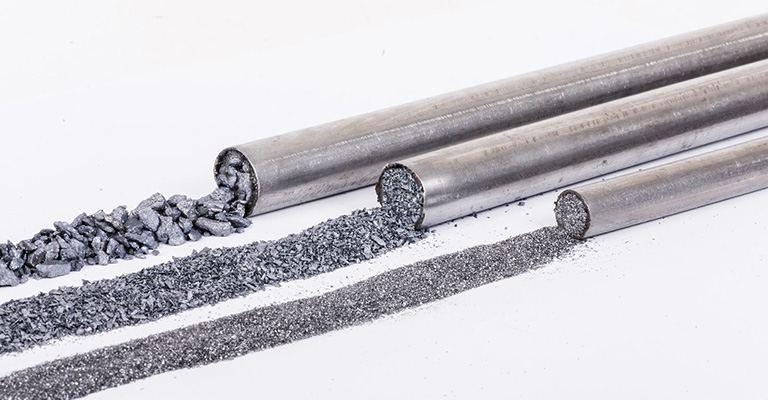

manganese and silicon. - Activated - contains additives that are inside

the twig. Their content is up to seven percent of the total volume of the

material. These are salts and oxides of alkali metals, particles that form a

slag. Additives help to form a neat weld, reduce metal spatter. This material

is used for welding with carbon dioxide.

- Powder - has a special structure; is a hollow

rod filled with a powder specially formulated to resist the environment and

oxygen. Its content can reach forty percent of the total parameters. The result

is improved combustion stability, the weld pool is protected from oxygen and

the seal is alloyed. There are two types of materials: submerged arc welding

(self-shielded) wire and carbon dioxide.

Powder

welding rods are very popular. The big plus is that there is no need for a

protective environment when using them.

But experts

in most cases believe that it is better not to resort to its use on an ongoing

basis, but to use copper-plated among the protective gas.

Including welders highlight the disadvantages of flux-cored wire:

- Higher cost;

- With its constant use - consumables become unusable faster;

- Large diameter of welding spatter;

- The weld seam is not very aesthetic and eye-catching.

And when

comparing the strength of the cored weld with copper-bonded wire, the welded

line is much weaker.

Where to buy wire?

Most often,

specialists on this issue turn to specialized stores, but everyone has the

opportunity, when purchasing forged elements to create a structure, to purchase

or order consumables on the website in one order.

Any metal

structures are produced by a welded method, therefore, in any case, consumables

and related products for welding will be needed, such as welding wire, welding electrodes,

gloves and materials for the primer and coating of the product.

In order to

place an order on the Artdeco® website, you will need to put the product in the

basket and fill in the data for delivery, including the opportunity to leave a

request for a call back from the product page or write to e-mail with contact

information and product request. You can also contact the specified phone

numbers of representative offices of a more convenient region for you.