They are used for

cleaning metal surfaces before welding, casting and soldering seams and joints

after welding, as well as for grinding all types - grinding wheels (grinding).

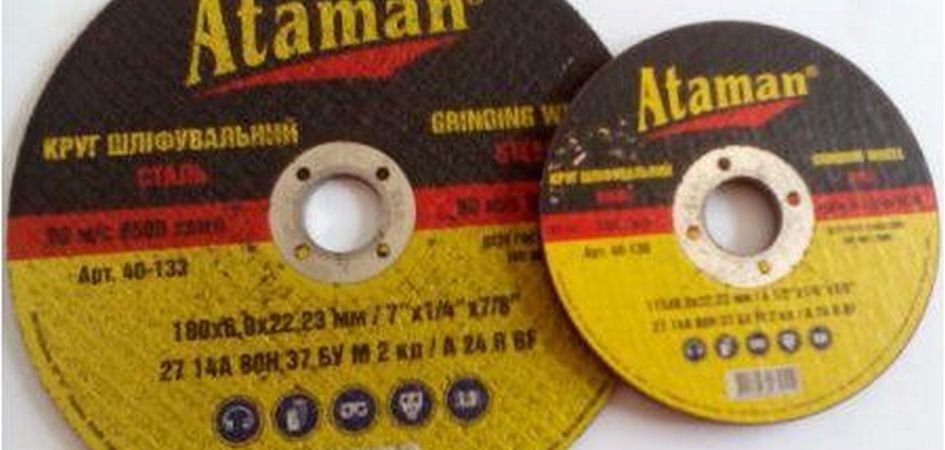

The diameter is similar to the dimensions of the cut-off wheels: 115-230mm,

diameters of 22 and 32mm are suitable, and the thickness differs significantly

from the cut-off wheels: 6.10 or 20 mm. Due to its design, the grinding wheel

(grinding) has high wear resistance, provides a volumetric contact area of

the abrasive cloth with the surface, which allows processing a large metal

plane in one pass. The cost of goods is sometimes higher than cut-off ones,

since more material is spent on their production.

The grinding wheel

(grinding) is often made without reinforcement, but since the thickness is

significant, the absence is not critical, the strength of the disc is already

high. To form a polished edge, the discs are set at an angle of 35-45 degrees

to the metal surface during operation.

polished edge, the discs are set at an angle of 35-45 degrees

to the metal surface during operation.

Why is a stripping element

needed?

Abrasive disc,

usually silicon carbide for metal and other materials. It is mainly used in

grinding machines, but some types of wheels can be installed on drills and

cleaning machines.

This consumable

copes well with welds, giving the product a good aesthetic appearance. In

addition, metal tools are worth buying for cleaning burrs, deposits, rust and

other corrosion, as well as for various types of coatings. It is often used to

remove damaged paint layers. It is important to note that the tool is engaged

not only in roughing, but also in delicate types of work. In addition, the

stripping components can be used to machine various corners and edges.

The element

handles sheet metal and structural steel well. The consumable tool has a long

service life and can be used for a long time.

It is worth

buying a grinding wheel (grinding) for metal work, carefully choosing the

dimensions. The maximum speed of the shredder reaches 80 m / s, which in the

worst case will lead to serious injury. Element sizes are usually between 115

mm and 230 mm. When choosing discs, as a rule, the diameter is taken into

account. However, the size and degree of grain are sometimes important.

How to choose a circle?

Before proceeding

with the purchase and order of a grinding tool, you need to pay attention to

the parameters that are important when choosing an element for high-quality

processing of the material and the work process:

- First, the area. The size of the plane that the tool can handle one time.

- Secondly, the equipment with which the nozzle is used. For example, a

grinding disc (sander) is ideal for use on a grinder. Differs in great power,

work productivity. Despite the high speed, processing is performed accurately

and accurately, without the slightest damage to the edge of the product.

Features of the grinding element

Nowadays, it is

impossible to achieve really high-quality grinding of uneven surfaces of

various types without cleaning components.

Therefore, the

elements are designed to work on concrete, stone, metal, stainless steel. You

can buy products in the online store with delivery to the warehouse of the

transport company or self-pickup in cities where Artdeco® is located. Its cost

is acceptable for many.

The grinding wheel

(grinding) has the following features:

- Economy;

- High efficiency;

- Minimum heating of the working area.

The component

used can be installed on: handheld units, angle grinders, straight grinders and

stationary equipment.

The main purpose is processing welded lines, grinding irregularities and protrusions of stone, concrete, cast iron, steel and non-ferrous metals. Therefore, the thickness is greater than that of abrasive cut-off wheels and must be at least 6 mm. They are usually equipped with a metal bushing that reinforces the structure. The end surface is rough or grooved. When choosing, it is necessary to take into account the granularity of the round material. It is also worth paying attention to the manufacturer.

How to order and buy?

The versatility

of the equipment lies in the fact that it can work both along the edge, in a

straight plane, and in joining the corners of parts of complex shapes. Abrasive

particles come in a variety of sizes. The larger, the better the layer of

material is removed and the less "grease" the working planes.

Particles with a particularly coarse grain size easily and better clean rust

and scale from welded seams.

The Artdeco®

online store provides professional assistance in choosing - by ordering a

Callback from the product page, you will receive a manager's advice. You can

order a quality grinding wheel (grinding) for a grinder at the best prices.